I so enjoyed this project! from concept - to laying out the design and building all the mechanisms. A surprise! (for me) - 3D printed parts can actually be used as working components. Mach3 CNC software so easy to use and free to download for trials, loads of information from an enormous following of on-line hobbyists like me, eager to share their discoveries - just love it!

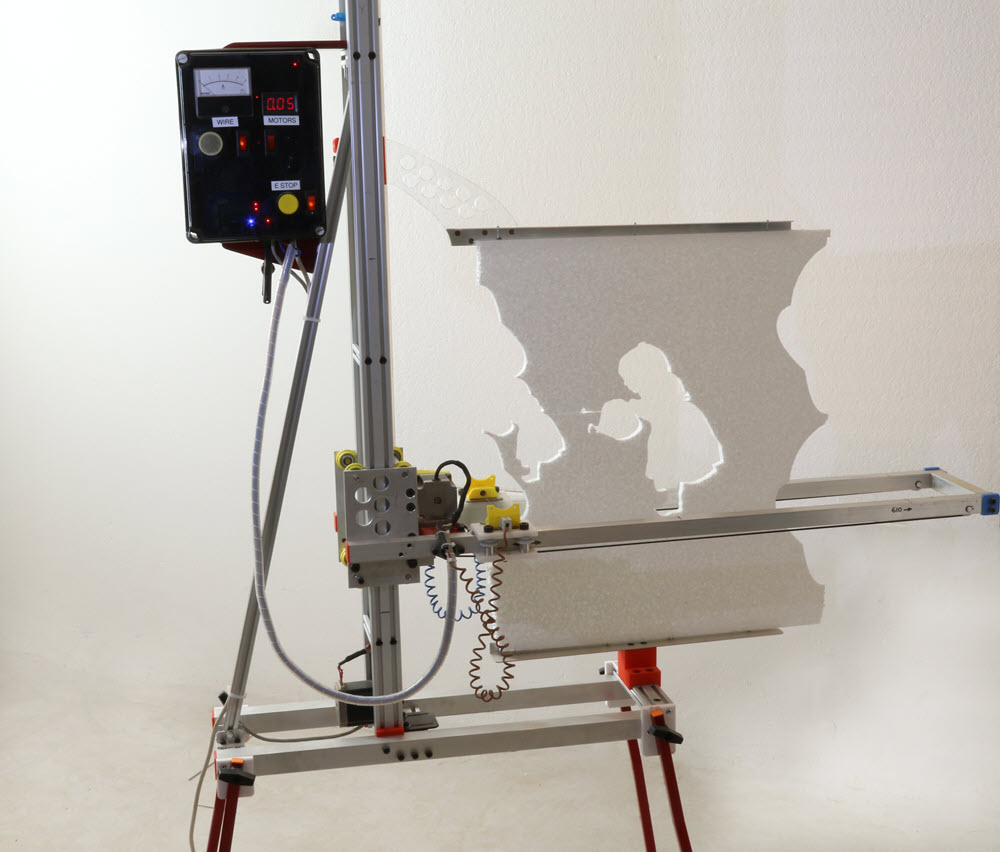

A HOT WIRE polystyrene cutter built for no reason at all! I liked the idea of designing and building a vertical 2D machine after seeing a video clip of a commercial unit. Maybe there would be a sensible use for it after(?).

CNC Polystyrene sheet cutter

There is a YouTube video of the build HERE