I found a 5W LED Laser on-line and set it up on my CNC Router to experiment with. Later I decided to build a 2D machine from scratch using supplies from on-line stores. I also tried my hand at a stop-motion video inspired by the work by Frank Howarth I later upgraded to a 15W Laser

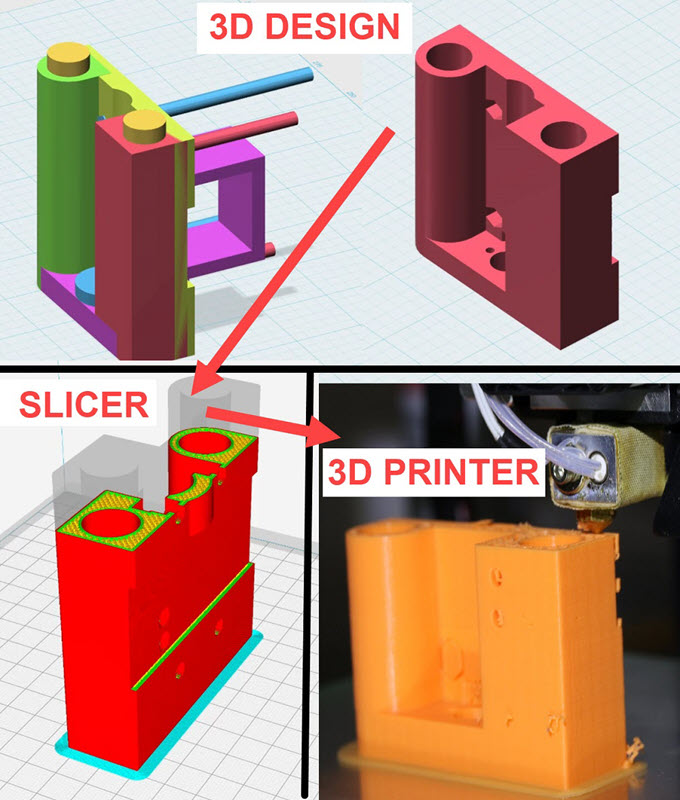

Many of the components were printed on the 3D printer which was a great learning curve. The low cost LED lasers are an easy way of getting into the hobby. The more powerful CO2 Lasers are bit daunting. The project took about 6 months.

Laser Engraver

There is a YouTube video of the build HERE